Utilization of Wood Vinegar from Charcoal Briquette Making Process

As the raw materials for charcoal briquette making machine is discarded biomass such as sawdust and agricultural wastes, the profit of manufacturing biochar briquettes is much higher than wood charcoal. And the production output and charcoal quality of biochar briquettes also surpasses that of traditional wood charcoal. Moreover, industrial wood charcoal briquetting plant has two common byproducts of high economic efficiency, wood tar and wood vinegar. The benefits will increase dramatically by collecting and making the best use of wood tar and wood vinegar.

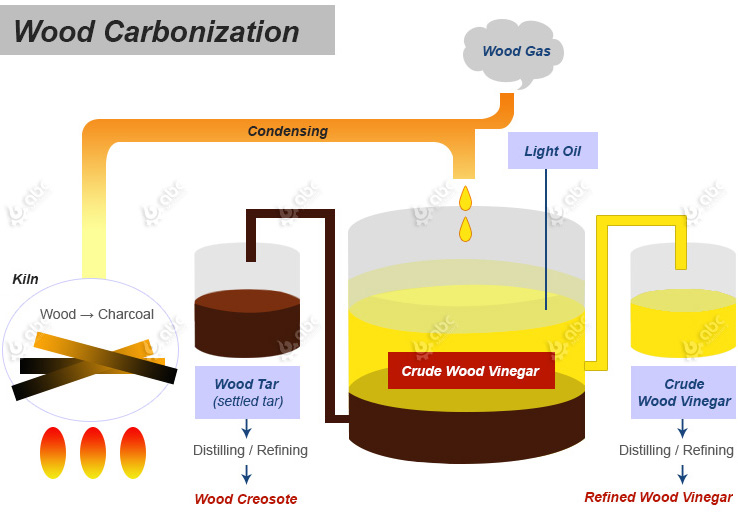

How Wood Vinegar is get from Charcoal Making Process?

Wood vinegar is also known as liquid smoke, mokusaku and pyroligneous acid. It is extracted from biomass through carbonization, contain more than 200 natural compounds primarily acetic acid, and formaldehyde. Here in this article, let’s talk about the development and utilization of wood vinegar from charcoal briquette making process.

The Application Status of Wood Vinegar

We all know that wood vinegar is a kind of charcoal processing byproducts with high economic value, but little is aware of how to use it. At present, wood vinegar has not been well utilized. In addition to the difficulty in collection and quality control, another main factor is the lack of purification and distillation technology of raw wood vinegar. There are some companies in China committed to wood vinegar purification & distillation, but most belong to lab production stage. Actually, another byproduct named bamboo vinegar has also faced the same development dilemma a few years before. If not make innovation in concept, we can only miss this great business opportunity.

Charcoal Briquettes Manufactured Factory

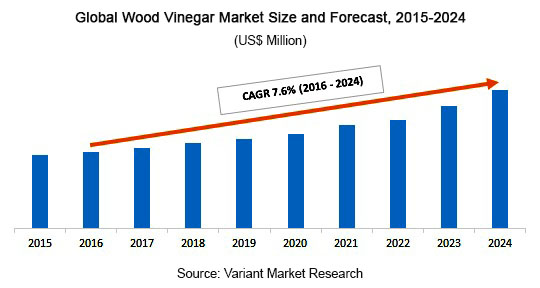

The global market size of wood vinegar was estimated at USD 3.7 million in 2016. The main application of wood vinegar is lised below:

- Agriculture

- Animal-Feed

- Food, Medicinal, and Consumer Products

- Others

Some manufactures of charcoal smoke recovery equipment claim that wood vinegar has very high commercial value, and many factories believe it. We have seen a lot of business plans of small charcoal making factory who put the wood vinegar as a profit point in the business plan report. We don’t know where the confidence of these factories come from, at least there is still a long way to go at the scale development and commercialization of wood vinegar.

Countries with Prospects for Wood Vinegar Development

| North America | Europe | Asia Pacific | Central & South America | Middle East & Africa |

|---|---|---|---|---|

| U.S. | Germany | China | Brazil | South Africa |

| Canada | UK | India | ||

| France | Japan | |||

| Australia |

Recently, we have attended a summit of charcoal industry. All participants in the summit were talking about the industry development, especially the application of wood vinegar liquid get from charcoal briquette production line. The comprehensive utilization of wood vinegar in Japan, South Korea and Taiwan was taken as an example. But one basic problem is ignored, that is market factors. Both South Korea and Taiwan are influenced deeply by Japanese culture, and their public are familiar with wood vinegar and bamboo vinegar. Besides, in Japan, some places have focused on wood vinegar collection for a very long time, most belong to low temperature collection (low temperature distillation below 150℃). Moreover, Japanese have an artisan spirit in charcoal industry. They attach great importance to the quality. That is why the quality of wood vinegar or bamboo vinegar made in Japan is among the best ones in the world.

How to distinguish the quality of wood vinegar?

The simplest way to distinguish the quality of wood vinegar is by sniffing. In addition to acetic acid flavor, you can smell a faint fragrance like grass or flower from high quality wood vinegar. Someone might think it is later added essence. But if you have been to the charcoal kiln of Wakayama in Japan, you will believe it is totally natural flavor. In most countries, they made the so-called "wood vinegar”, which are manufactured from mixed biomass material sources, and processed with no distillation range, making it an acrid smell of tar.

Is it true that wood vinegar has little chance in global market?

Low-end wood vinegar can only be used in the field of agriculture. However, the agriculture of most countries are mostly dependent on pesticides and fertilizers, which means wood vinegar has no competitive in this field. Absolutely no! In fact, on the contrary, it is the golden age of the vigorous development of wood vinegar. It is now a crucial period for the transition from barbaric growth to refined production. Many people in this field have begun to do practical processing design and technological innovation, rather than staying at the stage of research and report papers. Some factories already have manufactured mature separation equipment for fractionation of wood vinegar.

The key step of wood vinegar production, distillation and purification is becoming increasingly sophisticated.

As long as quality control is done well at the stage of wood vinegar collection, high purity and high quality wood vinegar can be produced. As basic raw material, this kind of high-purity wood vinegar is in great demand in the international market.

So if you own a charcoal making factory and plan to invest in wood vinegar production, attach importance to the quality of collection, even if the cost will increase. You should believe that the price will also increase. If you want to know the technical details of purified wood vinegar, you can leave a message or send an enquiry to info@briquette-machine.com. Let’s discuss the development and future of wood vinegar.

800~1000kg/h Sawdust Briquetting Assembly Line

800~1000kg/h Sawdust Briquetting Assembly Line

1Ton/Hour Wood Briquette Plant

1Ton/Hour Wood Briquette Plant

10 Ton Coal/Mineral Powder Briquetting Plant

10 Ton Coal/Mineral Powder Briquetting Plant