GCBA-II Briquette Machine

GCBA-II Briquetting Machine can process a wide range of biomass and wooden materials, the common types are listed below:

- Agriculture Wastes: soyabean husk, palm husk, sunflower stalk, wheat straw, paddy straw, bamboo dust, caster seed shells / stalk, cotton stalks, groundnut shell, sugarcane baggasse, mustard stalks, jute sticks, coir pitch, coffee husk, rice husk…

- Forestry Wastes: tree branches, logs, dried leaves, barks, straws…

- Industrial Wastes: veneer residues, wood chips, tea waste, tobacco waste, sawdust…

GCBA-II Briquetting Machine for Sale

GCBC-II Biomass Briquetting Machine

| Model | GCBA-II Briquetting Machine |

|---|---|

| Shapes of briquettes | Hollow Quadrangular or Hexagonal |

| Output kg/h | 300~350 kg/h |

| Motor Power (kw) | 22 kW |

| Electric heater (kw) | 5 kw |

| Size of briquettes | Dia.60mm/50mm |

| Size of inside hole | Dia.18mm/16mm |

| Density of briquettes | 1.3 g/cm3 |

| Weight(kg) | 780 kg |

| Overall dimension(mm) | 1500*1200*1600 mm |

| Warranty | 12 Months |

Features of GCBA-II Briquetting Machine

- GCBA series briquetting press machine is designed with automatic temperature control system.

- Screw press type: high efficiency and energy saving.

- There is a hole through the finished briquette, which can help improve the combustion efficiency.

- Reliable and stable working performance; reasonable structure design; easy operation and maintenance.

- High automatic; one operator is enough.

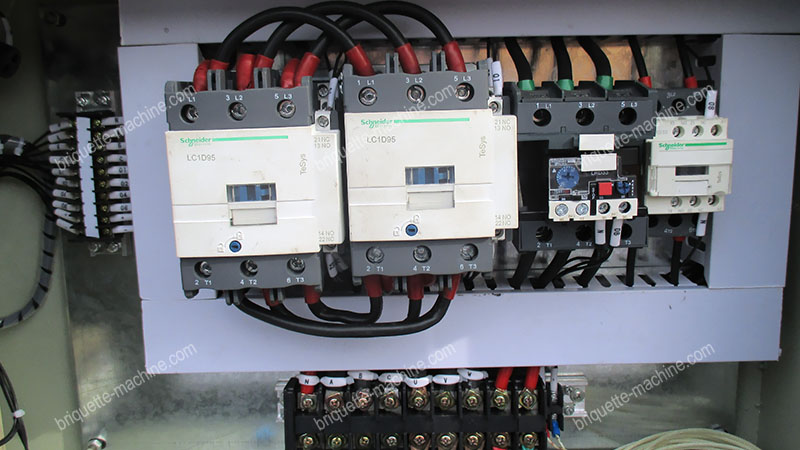

Photos of the Equipment Details

Here are some photos of the GCBA-II type wood briquettes making machine.

How to Build a Wood Briquetting Plant

Equipment of Wood Briquette Production Plant

Calorific value Cal/Kg and ash content of major agro wastes suitable for making briquettes.

| Agro Wastes | Cal. / Kg. | Ash Contents |

|---|---|---|

| Babool [Wood] | 4707 K. | 0.90% |

| Bagasse | 4380 K. | 1.80% |

| Bamboo Dust | 4160 K. | 8.00% |

| Barks Wood | 1270 K. | 4.40% |

| Castor Seed Shells | 3862 K. | 8.00% |

| Coffee Husk | 4045 K. | 5.30% |

| Coir Pitch | 4146 K. | 9.10% |

| Cotton Stalks / Chips | 4252 K. | 3.00% |

| Forestry Waste | 3000 K. | 7.00% |

| Groundnut Shell | 4524 K. | 3.80% |

| Jute Waste | 4428 K. | 3.00% |

| Mustard Shell | 4300 K. | 3.70% |

| Mustard Stalk | 4200 K. | 3.40% |

| Paddy Straw | 3469 K. | 15.50% |

| Palm Husk | 3900 K. | 4.90% |

| Rice Husks | 3200 K. | 19.20% |

| Saw Dust Briq. | 3898 K. | 8.20% |

| Soya bean Husk | 4170 K. | 4.10% |

| Sugarcane | 3996 K. | 10.00% |

| Sunflower Stalk | 4300 K. | 4.30% |

| Tea Waste | 4237 K. | 3.80% |

| Tobacco Waste | 2910 K. | 31.50% |

| Wheat Straw | 4100 K. | 8.00% |

| Wood Chips | 4785 K. | 1.20 % |

Maize Straw Briquettes Making Process

making Briquettes from Straw

For maize straw / corn stalk briquettes, the density can reach 1.0-1.2; the moisture content is 10-13%; the calorific value is about 3800-4500 kcal/kg. They can be used as industrial fuel or household fuel directly. They are easy to ignite, possess strong and stable combustion performance. Besides, as a kind of biomass briquette products, corn stalk or maize straw briquettes are featured with pollution free. There is no sulfur, phosphorus or other noxious substance in the smoke when burning. The ash after burning can also be used as plant ash. Maize straw briquettes are very popular in the world wide market, the main advantages are listed below:

- Environmentally friendly, economical and renewable.

- High calorific value (4000 Kcal/Kg)

- Low ash content and no fly ash during combustion.

- Pollution free: no sulfur or any hazardous material.

- Low moisture content, high density, high combustion efficiency.

- Unified rod-like shape, convenient to transport, use and store.

- I have a small joinery workshop and need a briquette machine. Extractor bags are large and hard to get rid of.I have a wood burner in there for winter so it be handy to make fuel. Could i buy one for around 5000 pounds ? Thanks

-

According to your investment, there are some models you can choose. We send the quotation of them, pls choose which model do you prefer to.

Contact us without any hesitation if any question. -

We are a Greek company interested in biomass briguette machine. Do you deliver worldwide?

Can you inform me of prices, availability and transportation cost to Greece? -

Yes, we deliver worldwide. So pls choose which kind of briquette machine you want. And pls also inform us the capacity of the briquette machine you want, then we can send the quotation.

For the transport to Greece, pls inform the seaport name, then we can check the cost with the shipping company. - I would like to find out if the GCBA Briquetting Machine can be sold and transported to Zambia.

- Yes, Zambia is a very close country to China. We been to Zambia for business visiting for many times. The transportation is not a problem.

- I'm interested to buy 200-500kg/h biomass briquette machine. Would you please inform me the price of the machine. The raw materials include wood chips, Sawdust, Coconut shell, Tree branches, Corn stalk, Others.

- We recommond GCBA-II briquette machine and the detailed quotation was send to your email. The raw materials you have should be crushed first before the briquette machine can take in,can you provide pictures and size of each? So we can make the best selection of the auxiliary equipment.

800~1000kg/h Sawdust Briquetting Assembly Line

800~1000kg/h Sawdust Briquetting Assembly Line

1Ton/Hour Wood Briquette Plant

1Ton/Hour Wood Briquette Plant

10 Ton Coal/Mineral Powder Briquetting Plant

10 Ton Coal/Mineral Powder Briquetting Plant

GCBA-II Briquette Machine

GCBA-II Briquette Machine

Wood Chipper

Wood Chipper

GCBC-IIA Briquette Machine

GCBC-IIA Briquette Machine