Cardboard Briquette Press

Cardboard briquette is an alternative source of fuel made by recycling waste stiff paper (card), hardboard or strawboard into dense briquettes. A cardboard briquette machine is used and the correct ratio of cardboard to wood is determined to sustain the process of recycling, an ash analysis is done to ensure impurities from the cardboard do not contaminate the materials.

ABC Machinery is one professional manufacturer and supplier for cardboard briquette pressing machinery, including building a complete cardboard briquette production line. For more details about machinery price and production cost, you can contact us freely!

Highlights Of Pressing Cardboard Briquette as Fuel

- Fuel shortage is a problem that results from inadequate wood, escalating costs of petroleum gas importation and the importance of using environmentally friendly energy sources in many nations. Cardboard briquettes are an alternative source of fuel for use in furnaces, since many people have old cardboards that are hard to dispose of; making use of such paper wastes to obtain fuel is the best innovative project.

- Briquettes are classified based on the waste paper, cardboard used in generation of the briquettes and the resulting density, index of resistance to impact humidity, calorific value and rate of relaxation.

- Calorific value of cardboard wastes is affected by moisture and hydrogen level which determines the energy content in the manufactured briquettes.

To summarize, with the decline in energy sources and the increasing concern to protect the environment, briquette fuel is an important fuel in industries as well as homes as the alternative source of energy. The Biomass Briquetting plant is now a promising and profitable project to invest in.

Briquetting Technologies of Cardboard Briquette Press for Sale

Briquetting technologies can be grouped into manual process, piston press densification, screw press densification and roll press densification based on the classification is based both on the equipment in use and the mechanical features.Manual press is widely used in countries with low technology as it comes with lower operational costs and skills requirements. The pressure used is low and the briquettes produced are not strong as in other methods.

Produced Cardboard Briquette With Different Briquetting Technologies

Here are our hot sale cardboard briquette press types: stamping/punching type briquette press and screw type briquette making machine manufacrtued with different briquetting technologies.

Stamping/Punching Type Briquette Pressing Machine

Piston Briquette Press for Industrial Briquetting Production

Piston Pressing Densification

The plunger is connected to a constantly rotating eccentric that applies pressure on the feed stock. An electric motor is used to drive the piston press to ensure appropriate power usage. This densification technology is used in mass production of cardboard briquettes.

NOTE: The briquettes made by the piston briquetting press are solid without holes. If you want to make hollow briquettes from cardboard and waste papers, screw type briquette press is what you need! You can contact us for more information!

Screw Type Cardboard Briquette Press at Low Cost

Screw briquette press is the most common used briquetting equipment. It is suitable for both small scale and medium scale briquetting mill. The finial briquettes are hollow. We offer twe series of screw briquetter: GCBA Series and GCBC Series. GCBA Series briquette presses are designed for small smale production, while GCBC Series briquette presses are recommended for medium briquetting plant.

GCBA Screw Briquette Press for Small Production

GCBC Screw Briquetting Press for Medium Production

Roller Pressing Densification

Two counter-rotating roles are used to generate pressure. This type of briquette press is commonly used for coal briquetting. The crushed coal materials are fed between the two rollers which compress the coal to the required density.

How to Turn Cardboard Wastes into Biomass Briquettes?

The briquetting press is a simple and effective machine that helps in densification. In addition, the machine is extremely flexible allowing it to process different materials. Wastes such as olive pomace, paper, tree branchs, agricultural residues and wood wastes are pre-treated, mechanically crushed, dried to reduce the moisture content and fed into the briquette press for densification.

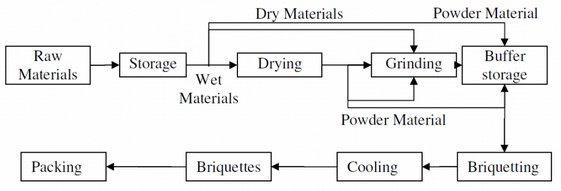

Complete Cardboard Briquette Production Process

Breakdown of the biomass materials occurs in a process called thermo-mechanical disintegration, a process where the materials are subjected to temperature and fiction. Temperature increase is important in separation of impurities from the treated material and melting others with low melting point to act as glue, sticking the materials together. Dehumidification as the process is known in helping getting rid of organic substances.

From Cardboard to Cardboard Briquettes Fuel

Essentially, briquetting is a densification process in which the cardboard and other kinds of biomass wastes are converted into convenient solid fuel. Pressure is an important element of the process because by agglomeration process using hydraulic control systems, the biomass is molded into required size and shape. This process involves strengthening of intermolecular forces and bonds that exist between the atoms.

Why Not Setting Up Your Cardboard Briquette Press Plant?

Anyang Best Complete Machinery Engineering Co., Ltd (ABC Machinery) deals principlally in exporting biomass briquette press and briquetting plant. We also provide customized turnkey project service from project plan, briquetting machinery manufacturing to onsite installing and debugging. Feel free to contact us if you are interested in start a cardboard briquetting business or briquetting production plant of other biomass materials.Here are some biomass briquette pressing machine projects successfully set up by ABC Machinery.

Successful Biomass Briquette Machine Plant Setup

| Project Name | Project Location |

|---|---|

| 1TPH Wood Briquette Production Equipment | Ethiopia |

| 500kg/h Screw Briquetting Plant | Russia |

| 1 Ton Glycyrrhiza Briquetting Plant | Tajikistan |

Video of Biomass Briquette Machine

Feel free to contact us if you are interested in starting a cardboard briquetting business or briquetting production plant of other biomass materials. We will provide you with the latest factory quotes and the most professional and comprehensive services.

- Why are the colors of the produced briquettes made by the same screw type briquette machines different?

- The normal surface of the finished briquettes from screw type briquette press is dark yellow. The black color is due to the surface carbonization caused by the high temperature of the bar making process, which affects the density of the bar. The light yellow bar is too low temperature or raw material material problems also affect the density. The dark yellow color is generally formed at 300-320 degrees and the density is 1.3 tons/m3.

- How long does it take to burn the finished biomass cardboard briquettes?

-

There are two combustion methods, which have different buring times.

one is the natural combustion method, that is, without external wind-assisted combustion, generally from the beginning of the combustion, into the charring and oxidation into ash, such as cooking, fireplace, etc. This process is about 2 hours.The other is put into the boiler combustion, with wind-assisted combustion, rapid heating, generally about half an hour to burn out.

800~1000kg/h Sawdust Briquetting Assembly Line

800~1000kg/h Sawdust Briquetting Assembly Line

1Ton/Hour Wood Briquette Plant

1Ton/Hour Wood Briquette Plant

10 Ton Coal/Mineral Powder Briquetting Plant

10 Ton Coal/Mineral Powder Briquetting Plant

GCBC-IIA Briquette Machine

GCBC-IIA Briquette Machine

Wood Chipper

Wood Chipper

GCBA-II Briquette Machine

GCBA-II Briquette Machine