How to Make Charcoal Briquettes?

Compared with old style charcoal, charcoal briquettes cost less and benefit more. They are hot selling in many countries including Europe, Japan and United States. To make charcoal briquettes, we need some specific equipments: crusher, dryer, charcoal molding machine and charcoal carbonization furnace. We are a professional manufacturer and supplier of charcoal briquettes making equipment, you can contact us for more information!

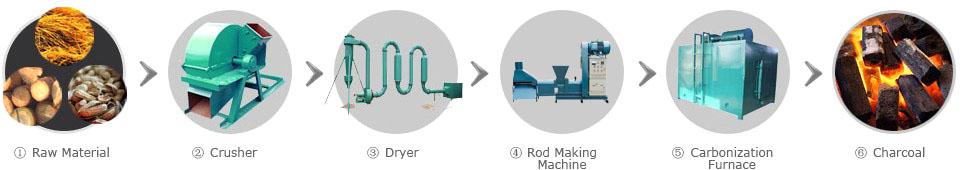

Main Process of Charcoal Briquettes Making

The above picture shows the common charcoal biruqette making process including crushing, drying, briquetting and carbonization. However, the process design could be different according to different raw material, production output and customer requirements. For example, if your raw material is sawdust and you want to make charcoal briquettes at home in small production, a single sawdust briquettes making machine is enough.

Mechanism Charcoal Vs Traditional Charcoal

Mechanism charcoal is very common in our life, such as barbecue shop, charcoal for homeuse, hotel and restaurant, etc. If you want to invest in charcoal production industry, you must be aware of how charcoal briquettes are made and what kinds of equipment is needed. And this is what ABC Machinery charcoal machine want to talk about in this article.

- Traditional charcoal products are made by carbonize wood, trunk or branches directly.

- Mechanism charcoal means making wood charcoal by mechanical equipment. It is made from wood or biomass wastes (such as sawdust, peanut shell, crop straw and so on) through compressing and carbonizing.

Both these two kinds of products can be called charcoal, but now in the market, we can't find old traditional charcoal easily. Not only because of its high price, but also because of the disadvantages of incomplete carbonization and smoke. The fact is, mechanism charcoal can fully replace old style charcoal with the following highlights.

Highlights of Mechanism Charcoal Briquettes Making Machine

- With the process with the charcoal briquette making machine, the final processed charcoal has high density, small volume, high specific gravity, burning resistance, reducing the cost of storage and transportation.

- Due to the high pressure inside the charcoal briquettes making machine, the final produced mechanism charcoal has high density, and the volume is equivalent to one-thirtieth of the same weight of straw, saving the storing space.

- Compared with burning coal, charcoal briquettes can be burned completely, with the same burning value as the industrial and power generation coal with 5000 calories. so, mechanism charcoal is more suitable for replacing the coal and other traditional fuels.

- Mechanical charcoal has low ignition point and low ash production volume, but the calorific value can reach 3200~6500 calories, it is a highly efficient solid fuel.

NOTE: if you have any questions about making mechanism charcoal, you can contact us for free!

What kind of machinery is needed to make charcoal briquettes?

Making mechanism charcoal needs a series of machinery, the following process will show you how charcoal briquettes are made.

Feel free to contact us and tell us your needs and requirements! We can offer you turnkey briquetting solutions for both mini scale, small scale and large industrial scale briquetting business plan!

Crush Raw Materials

Wood Crushing Machine

Crush machine is essential in most cases, because there are various kinds of biomass raw materials that can be used for making charcoal briquettes.

Suitable Raw Materials to Make Charcoal Briquettes

| Crop wastes | Stalks, straws, shells, |

|---|---|

| Wood residues | Sawdust, wood shavings and chips, branches etc. |

| Living waste | Waste paper, chopsticks etc. |

But if your raw material is in powder such as sawdust or bamboo powder, you can ignore this equipment. In charcoal production, crusher is used to crushing raw materials.

Reduce Moisture Content

The secoend machinery we must buy is dryer machine. If the raw matterial is too wet, the produced charcoal is prone to bending and fracture after carbonization. To make high quality charcoal sticks/briquettes, it is very important to dry the raw material to a certain moisture content.

Briquetting / Molding Machine

In charcoal production, molding machine is called charcoal making machine. Charcoal making machine or charcoal briquette machine is the key equipment for charcoal making. In this process, well prepared biomass materials will be compressed into rob shape. The end product of this process is semi-finished charcoal (only the surface of the briquettes are highly carbonized). Since the compressed briquettes we get here are not carbonized completely, we also call these semi-finished charcoal biomass briquettes.

Carbonization

Charcoal carbonization furnace is another machinery we must buy. This is the last step of charcoal making. Charcoal kiln is widely used for carbonization years ago. However, it has many disadvantages including produce big smoke, need longer carbonization time and more pollution to the environment. In recent years, more and more charcoal manufactruer begin to turn to charcoal carbonization furnace.

Video of Making Charcoal in Charcoal Making Plant

Buy a charcoal briquettes making machine for making low cost fuel when a cheap and reliable biomass raw material is ready in a short amount of time. Choosing reliable charcoal briquettes equipment manufacturers or suppliers and enjoy low prices and good customizable charcoal briquettes production line for commercial use and investing use. Have any questions about charcoal making or charcoal machine? Feel free to contact us!

800~1000kg/h Sawdust Briquetting Assembly Line

800~1000kg/h Sawdust Briquetting Assembly Line

1Ton/Hour Wood Briquette Plant

1Ton/Hour Wood Briquette Plant

10 Ton Coal/Mineral Powder Briquetting Plant

10 Ton Coal/Mineral Powder Briquetting Plant

GCBA-II Briquette Machine

GCBA-II Briquette Machine

GCBC-IIA Briquette Machine

GCBC-IIA Briquette Machine

Wood Chipper

Wood Chipper