Stamping Briquette Plant

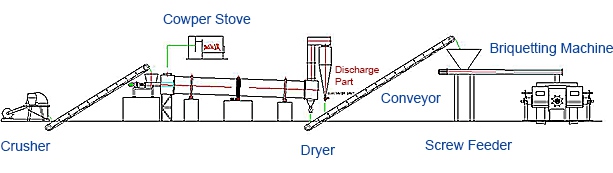

Mechanical Stamping Briquetting is a kind of curing process which can turn biomass materials such as crop straw, sawdust, barks, twigs and wood chips into log briquettes. Biomass log briquettes are the most promising and cost-effective energy resource for heating system. A complete briquetting plant generally includes crushing, drying, compressing, molding and packing process.

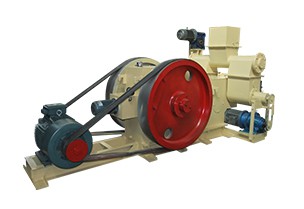

Mechanical Stamping Briquette Machine

(It can be equipped with screw conveyor or belt conveyor)

GC-MBP-1000 Briquette Machine for Sale

Details of This Briquettes Making Machine:

| Model | GC-MBP-1000 |

| Main parts | Briquetting machine |

| Conveyer | |

| Control cabinet | |

| Briquette Specification | Dia.:8mm, 70mm |

| Capacity | 0.5-0.8 t/hr |

| Density | 1000-1300kg/m3 |

| Power of main engine | 45KW |

| Weight | 7000kg |

| Overall dimension |

Host machine: 3.4mX2mX1.8m Control cabinet: 1.2mX0.6mX1.2m. |

| Number of operator | 2 |

| Installation space | About 80㎡ |

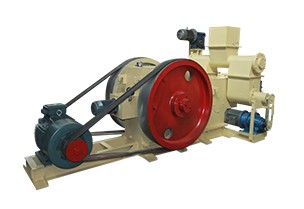

GC-MBP-2000 Briquette Machine for Sale

(The capacity is doubled compared with GC-MBP-1000 Type)

| Model | GC-MBP-2000 |

| Main parts | Briquetting machine |

| Feed box | |

| Lubrication pump | |

| Control cabinet | |

| Working Conditions | 380V 50HZ (temperaturer: -15℃~40℃) |

| Raw Material Moisture Content | Less than 20% |

| Capacity | 1.2~1.5Ton/Hour (different biomass materials have different output) |

| Density | 0.8~1.2Ton/m3 |

| Briquettes Diameter | 18mm, 30mm, 50mm, 70mm |

| Power of main engine | 55KW |

| Weight | 8000kg |

| Overall dimension | 3300x1500x1460 mm |

You are welcome to contact us for detailed information about this equipment!

Manufacturing Both Briquettes and Pellets

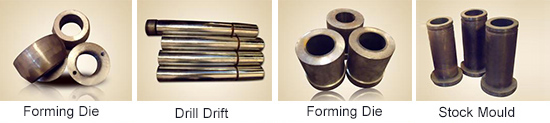

There are briquetting moulds for making biomass sticks and pelleting moulds for making small pellets:

Production of Moulds with Different Pore Size:

| Mould (Pore Size) | 8mm | 10mm | 22mm | 30mm | 70mm |

| Hole Number | 61 | 37 | 7 | 4 | 1 |

|

capacity (kg)

(Material is sawdust with moisture15%)

|

950 kg | 900 kg | 820 kg | 880 kg | 1200 kg |

Before briquetting, most raw materials need to be crushed into small fragments (≤20mm) and materials such as shells and kernels do not need to be crushed. The moisture percentage should be kept from 10% to 20%. Through feeding conveyor, the fragments will be sent to screw feeder and then be pushed into the inlet of briquette press machine. Then fuel briquettes will be formed.

Build A Briquetting Line

Mechanical Stamping Briquetting Plant

Features of Mechanical Stamping Briquette Machine:

- Processing Various Biomass Materials

- Convenient for Transportation and Storage

The finished fuel briquettes are solid rods (as shown below), small in size, moderate in density (0.8-1.2). They are convenient for both transportation and storage. Besides, it is also beneficial for the anaerobic gasification reaction inside the fuel briquettes and the calorific value of the raw material is improved to 3500-5000 kcal.

(We can offer different fuel briquette press plans to produce log briquettes with varied diameters.)

- Long Service Life, Good Strength, Toughness and Wearability

The core components of our mechanical stamping briquetting plant are made from special material and have been gone through heat treatment. So the service life is largely extended. The service life of the die can be 300-500 tons and that of punch can be 1000 tons. The spindle adopts No#45 steel forging under thermal refining and machining operation to mould. The surface is plated with Cr. Besides, this device adopts secondary compression technology which includes piston stamping and screw feeder pre-pressing.

Taking into account different characteristics of the material, speed regulating motor or variable frequency motor is equipped to regulate feeding rate, which enables different material to be fed uniformly. Specific type of motor can be adjusted according to customer’s demand.

The adopted bearing is imported from Germany, possessing the independent lubrication system, which ensures the lubrication and cooling among moving parts to achieve a normal running. The rack section is made from high strength steel plates and welded together by advanced welding technology. Moreover, with reasonable rib plate structure, our briquetting plant and briquette press machine can run smoothly under frequent impact loading.

- High Production Efficiency, Low Power Consumption (produce per ton of biomass briquettes consume 40 KWH).

- Can Mechanical Stamping Briquette Press process pine nut shell and pinecone?

- Sure, but the result is not as good as sawdust. FREE raw material test is available nοw! Send us your raw material sample and we can send back the final briquettes made by our machine along with briquetting test video.

- Is straw suitable for making briquettes? If it is then can I use this large mechanical stamping type briquette plant? I want to make 25mm straw briquettes.

- Straw is common raw materials for making biomass briquettes. This mechanical stamping briquette plant can be used to make 25mm straw briquettes. It is quite suitable for medium or large briquette production. Screw Briquette Press is suggested if you just want to make small scale briquettes.

800~1000kg/h Sawdust Briquetting Assembly Line

800~1000kg/h Sawdust Briquetting Assembly Line

1Ton/Hour Wood Briquette Plant

1Ton/Hour Wood Briquette Plant

10 Ton Coal/Mineral Powder Briquetting Plant

10 Ton Coal/Mineral Powder Briquetting Plant

Tree Shredder

Tree Shredder

Hammer Mill

Hammer Mill

GCBA-I Briquette Machine

GCBA-I Briquette Machine