Rice Husk Briquette & Pellet Machine

Home > Related Products >

Cotton Stalk

Crop Straw

Peanut Shell

Rice Husk

Wheat Straw

Wood

Biomass Pellets & Biomass Briquettes

φ8mm Pellets / Sticks

φ10mm Pellets / Sticks

φ22mm Pellets / Sticks

φ 30mm Pellets

φ70mm Briquettes (Rice Husk Made Rod)

φ 85mm Birquettes/Pellets

Why Make Rice Husk Pellets And Briquettes?

Rice Husk

Rice Husk Pellets & Briquettes Storage Stability

Now, let’s see if rice husk pellets and briquettes are easy to cause fire in the process of storage, and threat to safety production. Through tests, we found that the lighting time of rice husk pellets and briquettes is above 85s, similar to most wood materials. That is to say, the thermal stability of rice husk pellets and briquettes is in safe range.Combustion Performance

From the above table, we can see that under the same combustion condition, the rice husk biomass fuel has smaller heat loss and less ash release than coal. Rice husk biomass fuel has excellent combustion performance and some indicators are even superior to coal such as environmental performance indicators. Its carbon monoxide emission is only 0.02kg/kg and the carbon monoxide emission is only1.42 kg/kg, far lower than coal. Rice husk pellets and briquettes can meet all the requirements of pollution emission and combustion performance target. It is ideal energy source alternative with great prospects.

From the above table, we can see that under the same combustion condition, the rice husk biomass fuel has smaller heat loss and less ash release than coal. Rice husk biomass fuel has excellent combustion performance and some indicators are even superior to coal such as environmental performance indicators. Its carbon monoxide emission is only 0.02kg/kg and the carbon monoxide emission is only1.42 kg/kg, far lower than coal. Rice husk pellets and briquettes can meet all the requirements of pollution emission and combustion performance target. It is ideal energy source alternative with great prospects.How to Make Rice Husk Pellets and Briquettes?

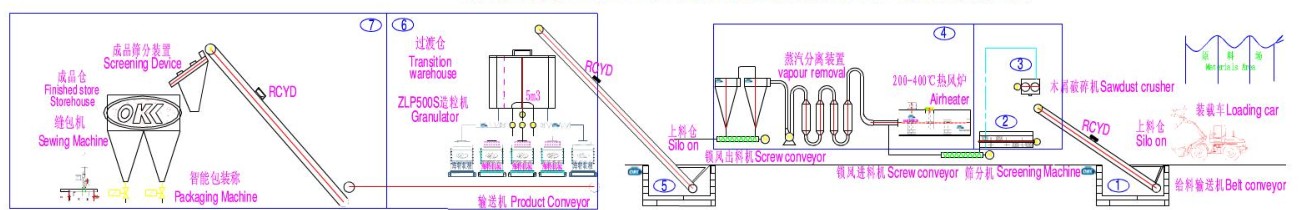

A complete pelletizing or briquetting process can be divided into: crushing, drying, mixing, delivery, molding (pelletizing or briquetting), cooling, testing and packaging.

Rice Husk Pellet / Briquette Production Line (click to enlarge)

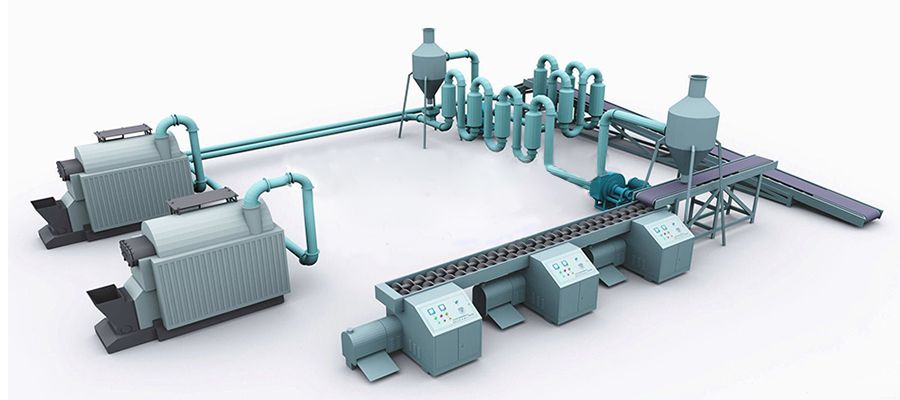

Complete Briquette Productin Line

Main Equipment List

Crusher, dryer, conveyor, rice husk pellet mill or rice husk briquette press, cooler, package machine.

- Rice Husk Pellet Mill

- Rce Husk Briquette Press

| Mechanical Stamping Briquette Press | Hydraulic Briquette Press | Screw Briquette Press Machine |

Pellet / Briquette Line Projects

Biomass Briquette Plant in South Korea

Biomass Briquette Plant in Egpyt

8 Ton Wood Pellet Production Line

Products

Briquetting Projects

800~1000kg/h Sawdust Briquetting Assembly Line

800~1000kg/h Sawdust Briquetting Assembly Line

1Ton/Hour Wood Briquette Plant

1Ton/Hour Wood Briquette Plant

10 Ton Coal/Mineral Powder Briquetting Plant

10 Ton Coal/Mineral Powder Briquetting Plant

Latest News

Featured Products

FAQs

Copyright © 2001- Anyang Best Complete Machinery Engineering Co., Ltd. All Rights Reserved.

GCBA-II Briquette Machine

GCBA-II Briquette Machine

GCBC-IIA Briquette Machine

GCBC-IIA Briquette Machine

Wood Chipper

Wood Chipper