Coal / Charcoal Briquette Plant

Charcoal chunk after biomass burned and small size waste charcoal broken in transportation and storage are all appropriate raw materials for this briquetting plant. Waste charcoal chunk and coal powder can be made into various shapes of BBQ / coal / charcoal briquettes (cube, small round, square, oval, pillow and bar shape etc).

Coal Briquette Making Line Projects

Want to start coal or charcoal briquettes manufacturing business? Plan to set up a complete full scale charcoal briquetting plant but don't know which charcoal making machine is suitable for you? Please don't hesitate to contact us to get more information about machinery for making charcoal and coal briquettes. We are always at your service!

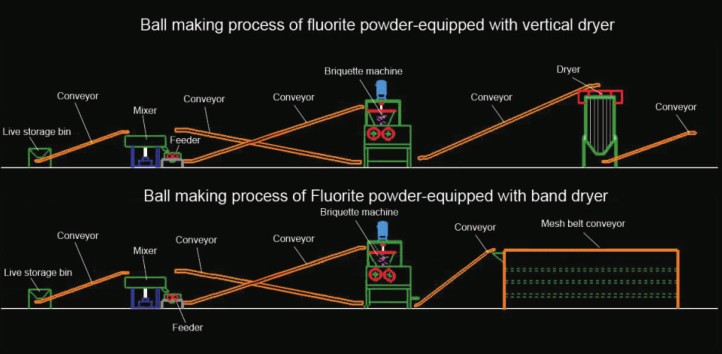

Process Flow of Coal / Charcoal Briquetting Plant:

Flow chart for Making Coal / Charcoal Briquettes from Coal Powder/Dust- Get raw material prepared: sieving, pulverizing the charcoal lumps/chunks or coal mateirals into fine powder.

- Get appropriate binder.

- Mixing process: mixing coal / charcoal powder with binders and some other additives if needed.

- Briquetting process/Extruding process: briquetting/extruding mixed charcoal powder into specific shape with charcoal making machine.

- Drying process: sun drying or automated tunnel type continuous drying

- Packing process: carton packing, gunny packing, paper packing.

Raw Material → Crusher → Grind Mill & Binder Mix → Conveyor → Coal / Charcoal Making Machine (Briquette Press or Extruder) → Drier/Natural Air-dry → Packing → Storage

CrusherThe Vertical Complex Crusher is a new type of rough grinding and fine crushing products that combined the domestic and foreign crushing technologies together, developed and designed by our team of highly qualified engineers on main technical parameter. It can be widely used in the medium cement plants to crush crude cement material and chamotte. It is an ideal piece of crushing equipment for of technical reconstruction or setting up a new cement production lines for a cement plant. Also it is suitable for crushing iron ore, sandstone, gypsum, slag, gangue, lump coal and other hard ore.Crusher special features:

|

Automatic Proportion Feeder

|

Double paddle mixer

|

Dryer

|

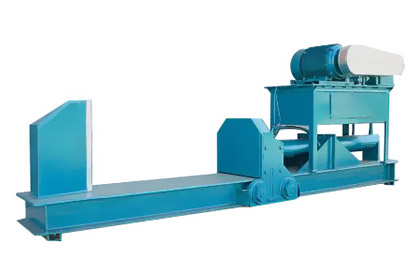

Belt conveyor

|

800~1000kg/h Sawdust Briquetting Assembly Line

800~1000kg/h Sawdust Briquetting Assembly Line

1Ton/Hour Wood Briquette Plant

1Ton/Hour Wood Briquette Plant

10 Ton Coal/Mineral Powder Briquetting Plant

10 Ton Coal/Mineral Powder Briquetting Plant

This unit is used to dry the charcoal briquettes outlet from briquette press machine.

This unit is used to dry the charcoal briquettes outlet from briquette press machine. GCBA-II Briquette Machine

GCBA-II Briquette Machine

Log Splitter

Log Splitter

GCBC-II Briquette Machine

GCBC-II Briquette Machine