Wood Pellet Line

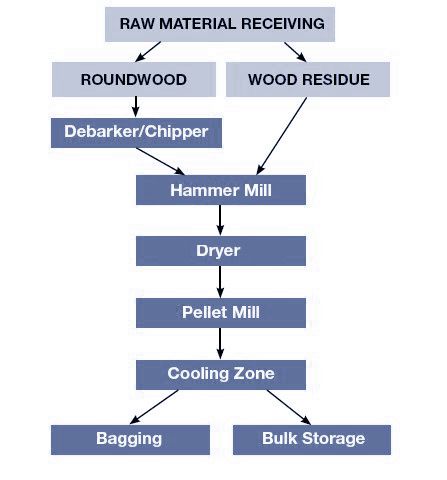

Manufacturing Process for Wood Pellets

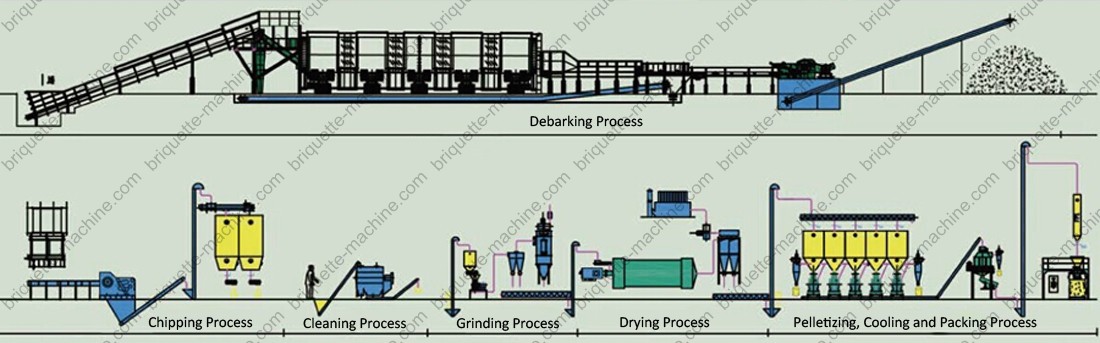

Complete Wood Pellet Production Process

The process of manufacturing fuel pellets involves placing ground biomass under high pressure and forcing it through a round opening called a “die.” When exposed to the appropriate conditions, the biomass “fuses” together, forming a solid mass. This process is known as “extrusion.” Some biomass (primarily wood) naturally forms high-quality fuel pellets, while other types of biomass may need additives to serve as a “binder” that holds the pellet together. However, the creation of the pellets is only a small step in the overall process of manufacturing fuel pellets. These steps involve feedstock grinding, moisture control, extrusion, cooling, and packaging. Each step must be carried out with care if the final product is to be of good quality.

★ Raw Material (Biomass and Wood Wastes)

The production of wood pellets begins with the generation of the raw material. In most cases this raw material is a by product of some other wood processing operation or residue, waste. Hardwood flooring mills are one example: They produce large quantities of clean (no bark or dirt), dry sawdust and small scrap blocks in their operations. This byproduct makes an ideal raw material for pellet production; however, as the interest in pellet production grows, some mills are generating pellet-making raw materials directly from trees (i.e. “round wood”).

★ Feedstock Grinding (Crushing)

Standard-sized pellet mills generally require biomass that is ground to particles that are no more than 3 millimeters in size. Several types of equipment are available to carry out this task. If the biomass is quite large and dense (e.g., wood), the material is first run through a “chipper,” and get wood chips. Then run through a hammer mill to reduce the particles to the required size. Smaller and softer biomass (e.g., straw) can be fed directly into the hammer mill without first being chipped.

★ Moisture Control (Drying)

Maintaining an appropriate moisture level in your feedstock is vital for overall quality of the final pellets. For wood, the required moisture level of the feedstock is at or near 15 percent. Other types of biomass have other requirements—you may need to experiment a bit. Moisture can be removed from the feedstock by oven-drying or by blowing hot air over or through the particles. If the feedstock is too dry, moisture can be added by injecting steam or water into the feedstock.

★ Extrusion (Pelletizing)

(Ring Die Pellet Mill and Produced Pellets)

The pellet is actually created in this step. A roller is used to compress the biomass against a heated metal plate called a “die.” The die includes several small holes drilled through it, which allow the biomass to be squeezed through under high temperature and pressure conditions. If the conditions are right, the biomass particles will fuse into a solid mass, thus turning into a pellet. A blade is typically used to slice the pellet to a predefined length as it exits the die. Some biomass tends to fuse together better than other biomass. Sawdust is an especially suitable feedstock for pelleting because the lignin that is naturally present in the wood acts as a glue to hold the pellet together. Grasses tend to not fuse nearly as well, and the resulting pellets are less dense and more easily broken. The proper combination of input material properties and pelleting equipment operation may minimize or eliminate this problem.

★ Cooling

(Counter-flow Cooler)

Pellets, as they leave the die, are quite hot (~150°C) and fairly soft. Therefore, they must be cooled and dried before they are ready for use or packing. This is usually achieved by blowing air through the pellets as they sit in a metal bin. The final moisture content of the pellets should be no higher than 8% .

★ Packaging (Bagging)

Once the pellets are formed and cooled, they are packaged in bags or stored in bulk. Pellets can be stored indefinitely but they must be kept dry to prevent deterioration.

Once the pellets are formed and cooled, they are packaged in bags or stored in bulk. Pellets can be stored indefinitely but they must be kept dry to prevent deterioration.

Energy Requirements for Pellet Manufacture

Pellet manufacture requires quite a bit of energy, both for drying damp feedstock and for running the various pieces of machinery. Large plants typically burn a portion of their feedstock to provide heat for drying, whereas smaller facilities often use other means. As a rule of thumb, a pelletizer requires between 50 and 100 kilowatts of electrical demand for every ton per hour of production capacity. In addition, electricity is usually needed to operate any chopping, grinding, drying, cooling, and bagging equipment that is in use.Demonstration of Our Wood Pellets Line

The followings are some of our wood pelleting projects. Feel free to contact us for detailed information! Finally, we welcome you to China and pay a visit to our factory to see the quality and performance of our Wood Pellets Line soon.

800~1000kg/h Sawdust Briquetting Assembly Line

800~1000kg/h Sawdust Briquetting Assembly Line

1Ton/Hour Wood Briquette Plant

1Ton/Hour Wood Briquette Plant

10 Ton Coal/Mineral Powder Briquetting Plant

10 Ton Coal/Mineral Powder Briquetting Plant

Tree Shredder

Tree Shredder

Hammer Mill

Hammer Mill

GCBA-I Briquette Machine

GCBA-I Briquette Machine